LIGHTWEIGHT CONCRETE MASONRY

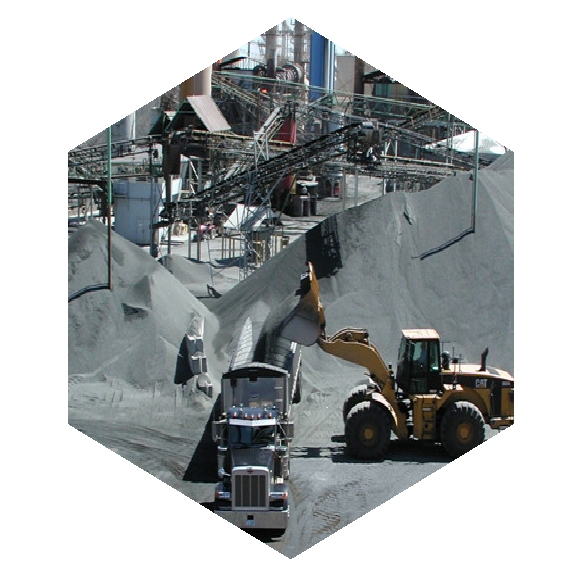

Masonry units made with STALITE are significantly lighter and easier to install. Compared to heavyweight units of the same size, weight reductions of up to 30% can be achieved.

Unlike aggregates made from byproducts and waste, STALITE masonry materials are pure and produced under carefully controlled conditions to assure performance. In addition, the superior strength of STALITE particles make a significant contribution to the overall dimensional stability, reduced shrinkage and toughness of masonry walls. As a result, lighter yet stronger masonry walls can be built in less time.

PERFORMANCE BENEFITS

High structural strength

Lightweight

Consistent, controlled size gradation

Dependable performance

High productivity

Materials Information

TEST REPORTS

SAFETY DATA

CERTIFICATION LETTER REQUEST

Material Handling and Preparation

MOISTURE CONDITIONING

Additional Information

GUIDE SPECIFICATIONS

DIVISION 4 MASONRY SUBMITTAL CHECKLIST

MASONRY SPECIFICATION

PROPRIETARY PRODUCTS and SYSTEMS

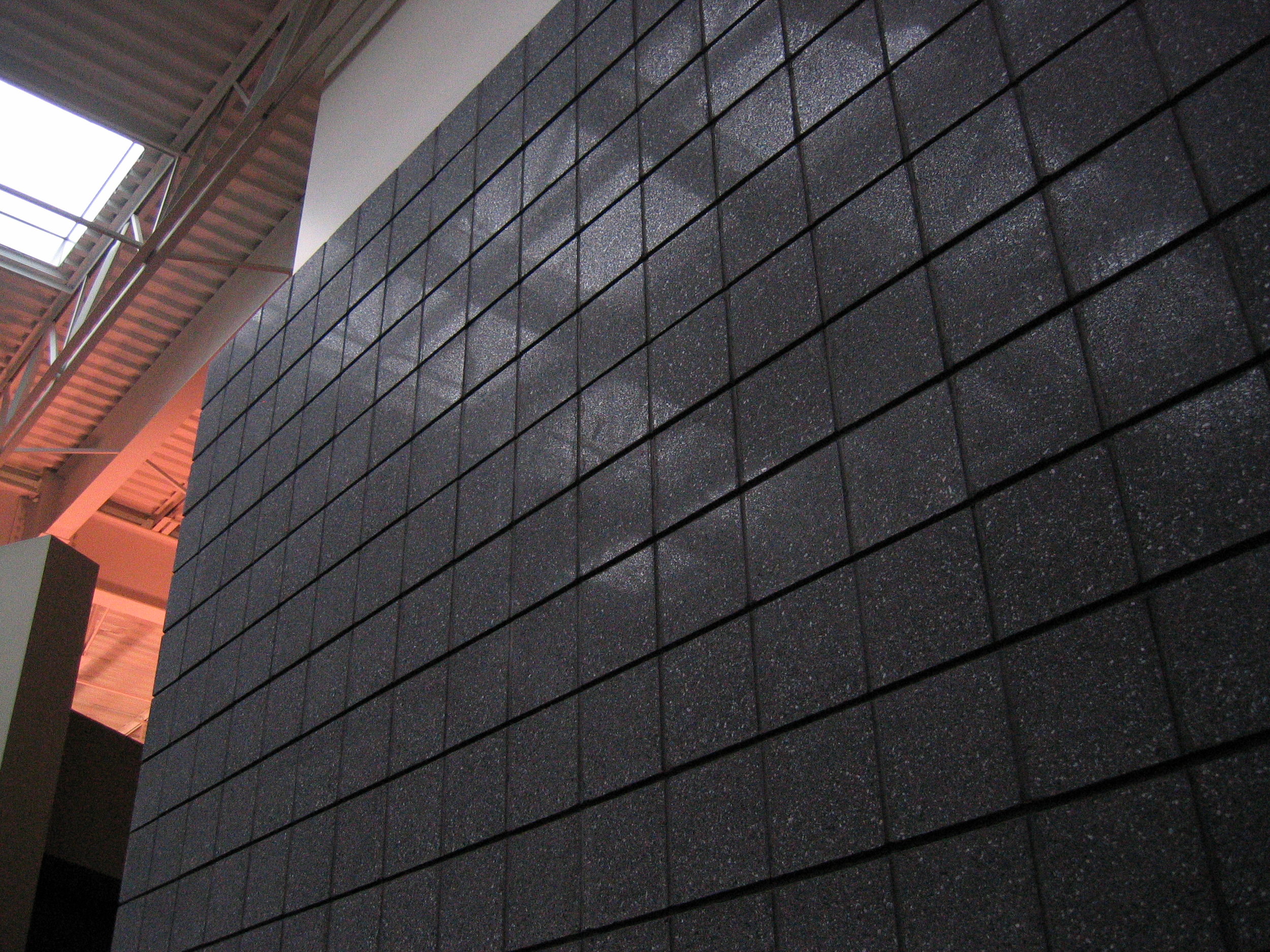

BENEFITS of LIGHTWEIGHT MASONRY

Lightweight masonry units made with STALITE provide for:

high sound absorption,

high insulation values,

high fire ratings,

and single wythe loadbearing walls that are finished on both sides.

These properties increase the intrinsic value of the investment and extend the life and utility of the structures.

LIGHTWEIGHT MASONRY gallery

““Use of lightweight aggregates has the potential to reduce costs and construction time for concrete masonry walls as well as improve performance.””

Buildings

Hardscapes

Case Studies & Project Profiles

Lightweight Masonry Projects

Location: Raleigh, NC

Architect: HS Annis Architect

General Contractor: Annis Building Corporation

Masonry Contractor: Moxley Masonry

Masonry framed homes can be designed in any shape or size. The versatility and flexibility is unlimited with a variety of curves and angles, texture, color and size options. Due to the strength of concrete masonry, large wall areas and impressive open spaces make for a unique interior design.

Masonry Framed Home 3

Cabarras County Detention Center

Architect: Ware Bonsall Architects

General Contractor: Turner Construction Company

Masonry Contractor: Pompano Masonry, Inc.

Architect: LS3P Associates, Ltd.

General Contractor: Devere Construction Company

Masonry Contractor: Doug's Masonry

Architect: Robert Johnson

General Contractor: Shelco, Inc.

Masonry Contractor: KB Masonry

The Lowes Foods project used 30,000

lightweight concrete masonry units.

The New Birth of Charlotte Worship Center project used 35,000 lightweight concrete masonry units.

Time-Warner Arena

The Time-Warner Cable Arena project is 780,000 sq. ft. and

used 500,000 lightweight concrete masonry units

Architect: The Lawrence Group

General Contractor: Global Building Company